Get more value from your biofuel plant

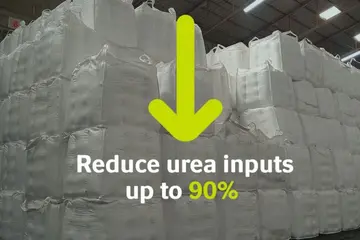

Your goal is to increase ethanol and co-product yields through smooth processing and production efficiency gains. You also need to boost your sustainability profile through a smaller carbon footprint and lower chemical and water use. Our portfolio of solutions and services are designed to help you meet your production and sustainability goals. And our industry-leading education program ensures that your people can get the most from our products and from your plant.

We develop products that focus on your needs, so each innovation we bring to market helps boost your profitability.