Next yeast product lifts yields, robustness

Innova® Lift responds to ethanol producers looking for greater stress tolerance and better yields.

Novozymes today launched its next yeast technology, Innova Lift, for the starch-based ethanol industry. The product follows the launch earlier this year of an ambitious yeast platform, Innova, and the first product, Drive.

“We are continuing to deliver on our promise to quickly bring innovative yeast and enzymes to a market that is clearly looking for exactly that,” says Brian Brazeau, Novozymes’ Vice President for Biofuels Commercial. “Lift targets ethanol plants with long fermentation times – delivering greater tolerance to common stressors such as high temperature and organic acids.”

An ethanol plant’s fermentation is a crucial part of securing better yields. However, the fermentation process is also tricky; even small spikes in temperature or organic acid levels can cause disruptions. Having the opportunity to use a robust yeast can help producers meet these two key challenges.

Innova Lift expresses a glucoamylase that is two times more effective at converting difficult-to-reach starch. When paired with advanced enzyme solutions, Lift also has the potential to significantly increase ethanol yields, reduce fermentation risks and eliminate costly inputs, while improving performance reliability.

Until now, yeast strains have remained largely unchanged

Novozymes’ new yeast platform, Innova, has been founded on new S. cerevisiae yeast – utilizing proprietary methods to enhance its ability to withstand the rigors of today’s ethanol production processes and goals.

“The ethanol industry has clearly been longing for new and reliable innovation for a very long time, not just updates of old products,” Brazeau adds.

Numerous ethanol plants have begun using Novozymes’ yeast since the introduction of the Innova platform and are realizing the benefits in productivity.

“By leveraging the synergies of our enzymes, yeast, and technical services, Novozymes has reset performance expectations for yeast and fermentation by delivering the most advanced and useful solutions, based on customer needs,” says Brian Brazeau.

Why is yeast vital for ethanol production?

Yeast converts raw materials into ethanol. Corn goes into the plant and is broken down by enzymes to prepare it for fermentation. During fermentation, yeast is added. The yeast consumes the raw materials and releases ethanol and carbon dioxide. Ethanol producers spend a lot of time and energy ensuring that the right conditions exist for yeast to thrive. The stronger and more efficient the yeast, the better able it is to tolerate production stresses and generate ethanol – improving productivity and profitability.

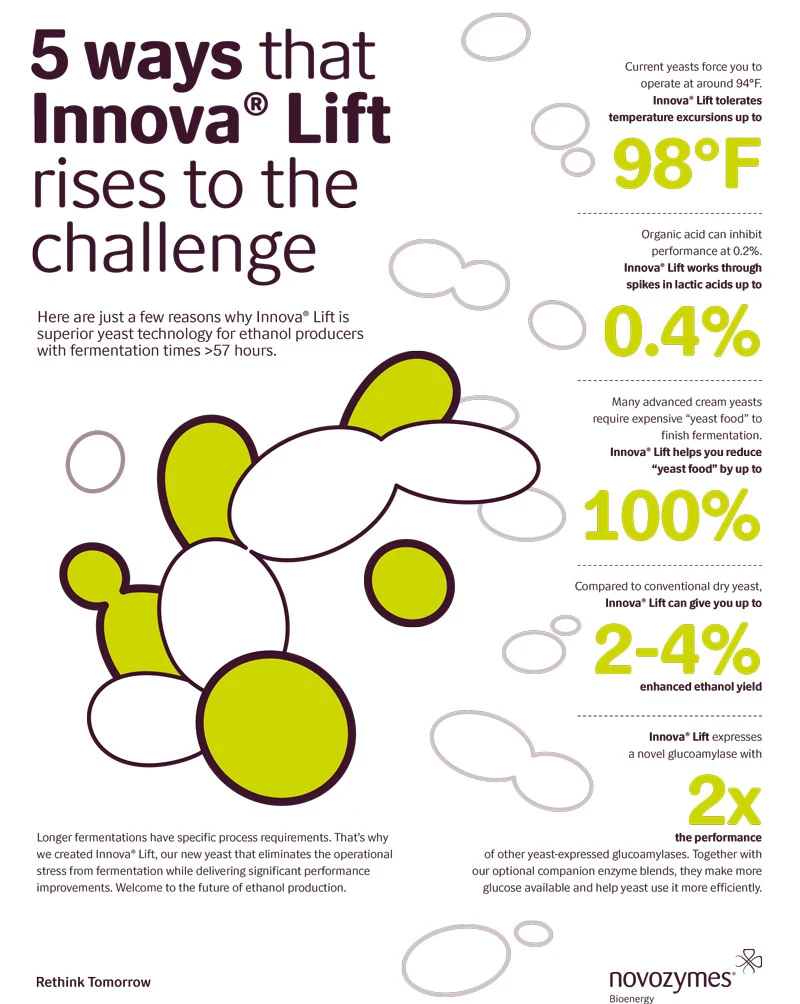

Innova Lift: Key numbers

Lift is targeted to plants with longer fermentation times, generally 57 hours or more – delivering greater tolerance to common causes of yeast stress, the opportunity for better yields, and eliminating costly yeast food, which is common amongst competitive cream yeast.

- Lift remains effective through fermentation temperature spikes up to 98°F (36.7°C) – significantly higher than the 94°F that most other yeasts can tolerate

- Producers can eliminate downtime, cut cooling costs and maximize the plants’ efficiency, whilst achieving up to 2-4% better yields, compared to conventional dry yeasts

Contact