BioRas® Balance reduces waiting time for RAS restart after disinfection with hydrogen peroxide

BioRas® Balance reduces waiting time for RAS restart after disinfection with hydrogen peroxide

New study tests the efficacy of BioRas® Balance to break down hydrogen peroxide in aquaculture.

A safe water system is crucial for maintaining fish health and routine maintenance such as disinfection procedures play an important role in preventing pathogens from entering farms. However, maintaining the delicate balance inside a recirculating aquaculture system (RAS) is no easy task and disinfectants, such as hydrogen peroxide, can have detrimental effects on parts of the system; notably the biofilter.

The biofilter inside a RAS is home to critical populations of nitrifying bacteria – whose job is to oxidize harmful animal byproducts. When these bacterial populations are compromised, ammonia nitrogen and nitrite nitrogen accumulate, creating an unhealthy environment for aquaculture.

Did You Know

- A survey conducted in 2020 highlighted that the most common disinfectant used in the Norwegian RAS industry is hydrogen peroxide (Lazado & Good, 2020).

- Hydrogen peroxide application impacts biofilter performance even at low dosages (Arvin, Møller, & Pedersen, 2010) (Pedersen, Good, & Pedersen, 2012).

- To reduce potential negative impact of disinfection protocols, most producers wait 1 week before restart (Lazado & Good, 2020).

Hydrogen peroxide is environmentally benign but can harm the beneficial bacteria in biofilters. Lowering the dosage to a level that is safe for biofilters is also problematic, as it lowers the effectiveness against certain pathogens. This, in a nutshell, is the issue with hydrogen peroxide.

In search of a sustainable solution

That’s where BioRas® Balance comes in. When the tank is shut down for disinfection, this enzymatic solution accelerates the natural break-down of hydrogen peroxide in water in as little as 10 minutes. By the time the system is restarted, and water is again circulating, the hydrogen peroxide is almost completely eradicated, turning into water and oxygen and therefore no longer harmful to the biofilter. BioRas® Balance is considered safe to use and efficacious in all aquaculture systems regardless of temperature or salinity.

The study conducted by Novozymes and the Freshwater Institute- part of the Conservation Fund- shows that when BioRas® Balance is used, it’s possible to break down hydrogen peroxide in RAS tank water at both therapeutic and disinfection-level concentrations with no adverse effect on the biofilters.

Study

In the trial, Atlantic salmon were hatched onsite and then grown in freshwater RAS. To begin the study, 216 of these fish were stocked randomly into 12 partial RAS.

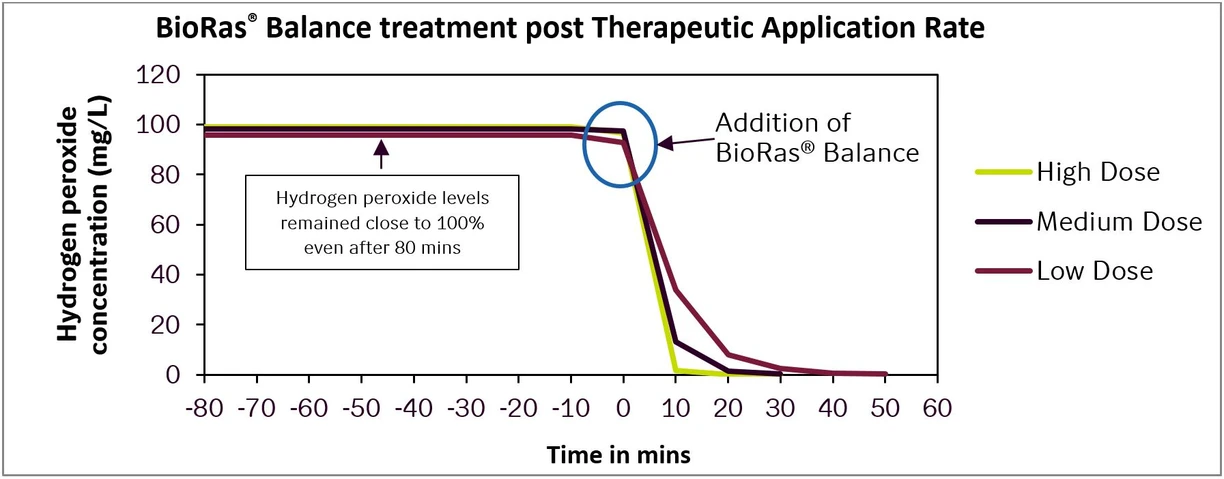

After the fish acclimated, the researchers carried out static tank treatments – meaning that the water recirculation had been stopped for the duration of the treatments. This simulated the therapeutic treatment using hydrogen peroxide that’s typically carried out for bacterial gill disease. After 80 minutes of static treatment, the hydrogen peroxide levels remained at near 100% of the initial dose (see graph).

After 80 minutes, BioRas® Balance was added, and hydrogen peroxide concentrations were analyzed at 10-minute intervals until the concentrations were considered negligible.

Results

The study showed that treatment resulted in >99% decay of hydrogen peroxide within 10 mins when using the highest dosage of BioRas® Balance.

A second trial was carried out to simulate a typical disinfection event where higher concentrations of hydrogen peroxide are typically used. Similar results were observed in trial 2, proving that BioRas® Balance can reduce hydrogen peroxide to safe levels for both therapeutic applications in the rearing tanks and for neutralization of H2O2 prior to discharge.Overall, the results of these experiments are encouraging for RAS farmers, who now have a powerful new combination of tools for treating infected animals in the rearing phase that is antibiotic free, leaves no chemical residues, and will not negatively impact the biofilter thus allowing for treatment of animals without negatively impacting normal operations or fish quality.

Conclusions

In cases of total system or purge tank disinfection where the biofilter and animal welfare not a concern farmers can be left with enormous amounts of hydrogen-peroxide-laden water. The second trial shows that farmers now have options for pre-treating the water safely and free of residuals before discharge without jeopardizing their permits. With proper use of BioRas® Balance, we see that the risk of these infractions is eliminated, and the RAS can be restarted significantly more quickly than without the enzyme addition.

References

Arvin, E., Møller, M. S., & Pedersen, L.-F. (2010). Degradation and effect of hydrogen peroxide in small-scale recirculation aquaculture system biofilters. Aquaculture Research, 1113-1122.

Lazado, C. C., & Good, C. (2020). Survey findings of disinfection strategies at selected Norwegian and North America Land-based RAS Facilities: A comparative insight. Aquaculture Volume 532, 532. doi:https://doi.org/10.1016/j.aquaculture.2020.736038

Pedersen, L., Good, C. M., & Pedersen, P. B. (2012). Low-Dose Hydrogen Peroxide Application in Closed Recirculating Aquaculture Systems. North Amarican Journal of Aquaculture, 100-106.

BioRas® Balance

BioRas® Balance rapidly neutralizes residual hydrogen peroxide (H2O2) from both therapeutic and disinfection doses in RAS facilities. In less than 10 minutes, BioRas® Balance achieves below-detectable H2O2 levels. That allows your facility to balance robust biosecurity with fast turnaround between batches. All while improving animal health, sustainability and regulatory compliance. BioRas® Balance is part of our family of biological solutions for RAS aquaculture.