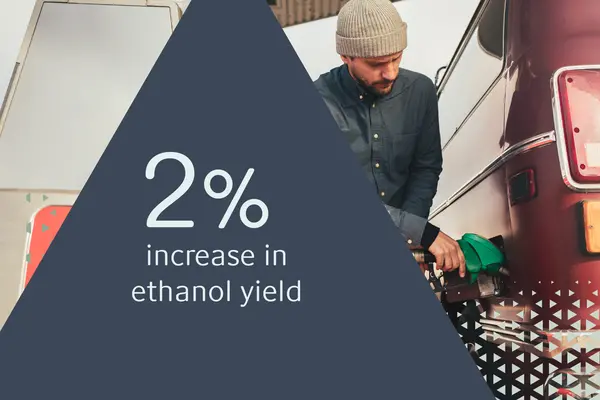

Unrealized potential

You’ve been pursuing an obvious, measurable change in your ethanol plant’s operational performance and profitability.

However, you continue to experience bottlenecks restricting your ability to fully convert the potential of your investment. This results in a loss in efficiency, revenue, and market share.