“Doing well” versus “doing good”

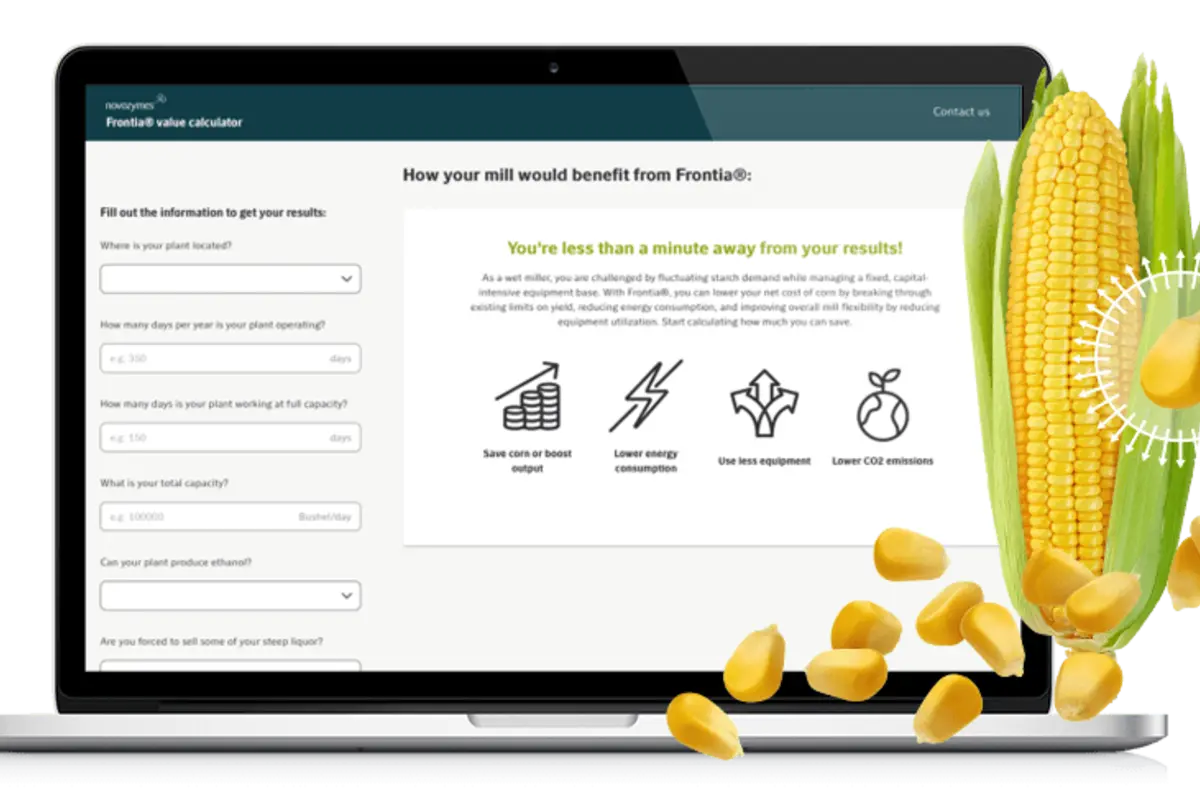

As a corn wet miller, your metric for “doing well” is remaining competitive by supplying the right amount of starch with the right contribution margin. That generally means finding ways to increase grind rate and capacity.

At the same time, it’s your responsibility to “do good: by making strides toward reducing your plant’s environmental footprint and CO2 emissions. Unfortunately, these two priorities don’t always go hand-in-hand.