The biodiesel industry is changing...and technology can fuel the transition

Biodiesel producers recognize feedstock flexibility as a key challenge in transitioning away from used cooking oil and vegetable oils. In fact, a recent survey* found that increasing flexibility will likely be the dominant industry trend over the next decade.

However, with no consensus on the choice of new feedstocks, producers foresee technical barriers to diversifying their feedstock base. Incorporating waste-based and advanced feedstocks and dealing with variable quality are critical to remaining competitive. Many producers, however, simply don’t have this capability.

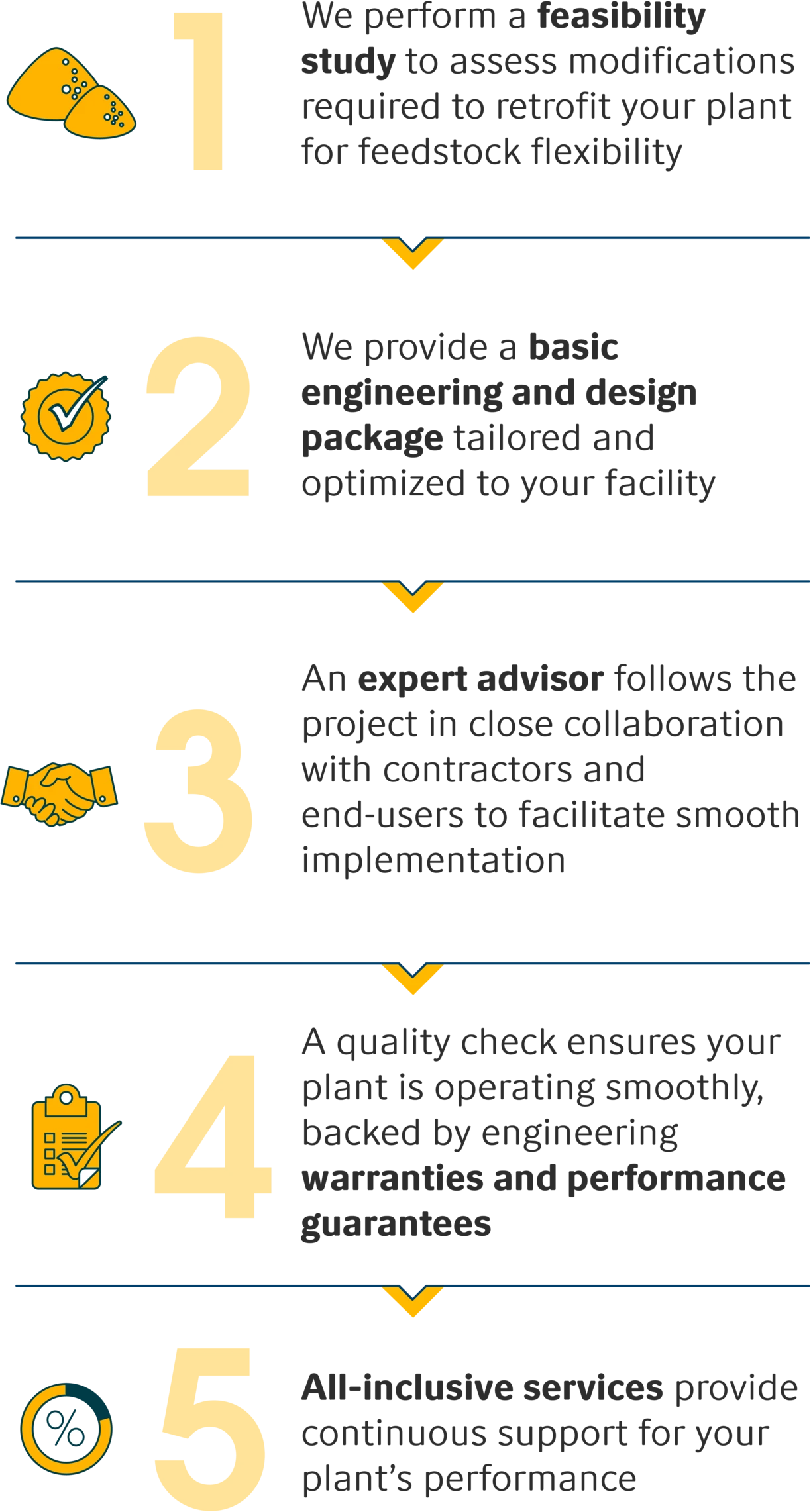

But what if you could make feedstock decisions based on cost and availability instead of being constrained by your own processing capabilities–and put your plant on the path to waste-based biodiesel with a performance guarantee?

*Novozymes survey of more than 15 European FAME producers