Break down triglycerides to reduce pitch deposits

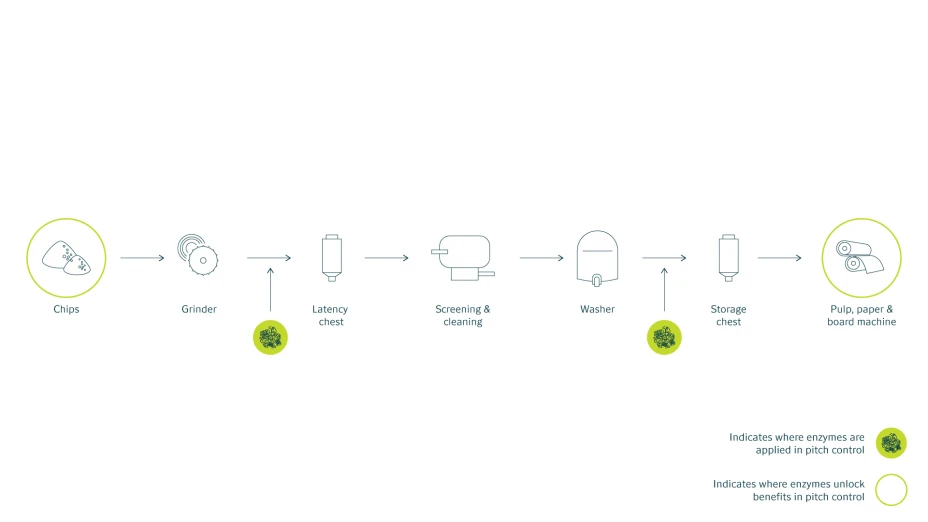

During mechanical pulping, natural triglycerides are released and retained within the pulp fiber. Triglycerides are a major component of pitch, so they contribute to the formation of deposits on rollers, wires and the paper sheet. On the fiber surface, they can also interfere with interfiber bonding and reduce paper strength. Our enzymatic solutions for pitch control break down triglycerides. That considerably reduces the level of pitch deposition on your paper machine. It also improves the quality and strength of your paper and board.