The broadest pH and temperature range

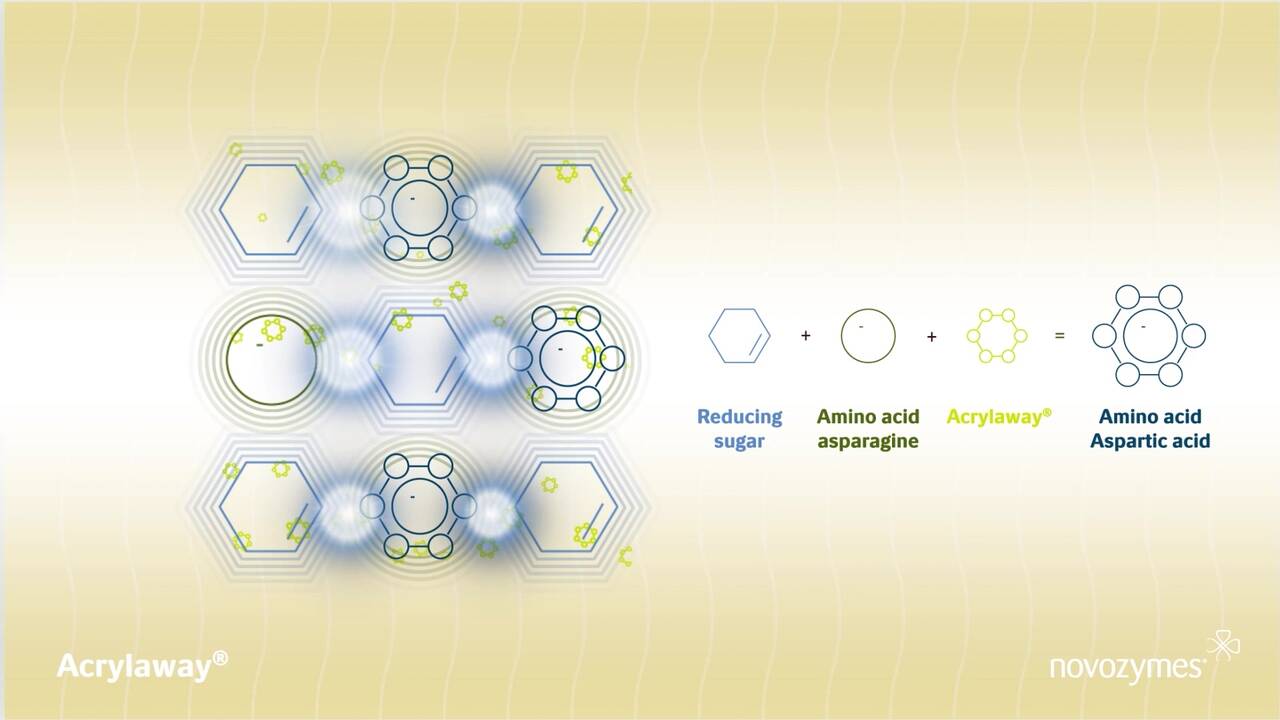

Acrylaway® is a processing aid that can be easily added to most baking operations with few or no process changes. Because it is the asparaginase with the broadest pH and temperature range, it offers producers the greatest degree of flexibility and consistent results.